4 Types of Diesel Pumps That Are In Function

- annawrench1315

- Oct 9, 2021

- 3 min read

Updated: Nov 25, 2025

Diesel engine cars are getting rarer. If you happen to own an old vehicle or if you are one of those who still prefer to buy an old model diesel car even in the 21st century then you also must choose the right types of diesel pumps along with it. Most people don’t have any idea about the types of diesel pumps so in this article we are going to give you detailed information on the types of diesel pumps and how you can use them.

Common Rail Fuel Injection Pumps

This type of diesel pump is electronically controlled. It is developed to meet the exhaust regulations of the current generation. There are many parts to it such as a supply pump, common rail, electronically controlled injectors, a few sensors that keep operating to check and keep monitoring the running conditions, and a computer that an operator will controls to operate all these devices. There is an engine within all these diesel pumps that produce and emanates high-pressure fuel. The common rail is present to distribute the fuel to the various injectors that are mounted on each cylinder of an engine.

Distributor Fuel Injection Pump

It is also an electronically controlled diesel pump that has many sensors on it along with an electronically controlled unit with an actuator. Just like in the common rail pump here the sensors are usually placed to detect the running condition of the engine, send and receive signals to the controlling unit which is a computer that an operator controls and monitor each move. The amount of fuel coming out is controlled by the actuator. The actuator is connected with the controlling unit that is manually operated with input signals by the operator controlling the computer. The control unit is advanced and it can automatically keep a check on calculating which signals it receives thereby controlling the fuel injection from the actuators to keep the flow of fuel optimum for the engine while running.

In-Line Fuel Injection Pump

It is one among the two mechanically controlled diesel pumps fuel systems that match along with the engine cylinders and controlling the fuel pressure mechanisms within. This type of pump finds its major use in medium to large trucks while construction machinery also uses this type of diesel pump. There is a camshaft present that will drive and control the fuel pressure and the amount of fuel injection that is to be done within the pump body. There are elements present in the body that control how much fuel injection needs to be done to feed and fuel each engine cylinder and to keep them running in the optimum condition.

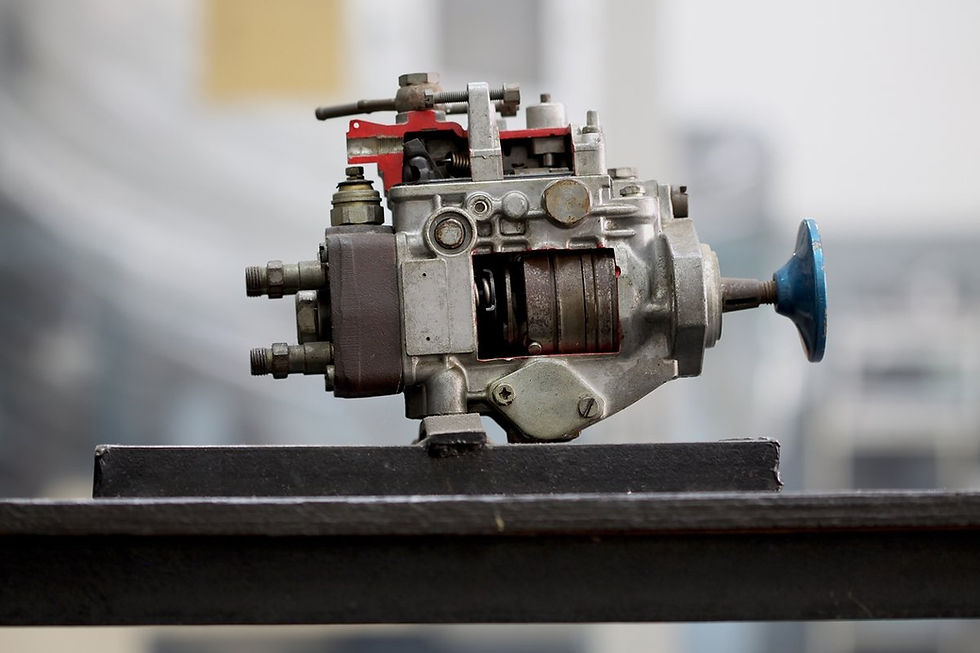

Distributor Injection Pump

This is the second type of mechanically controlled diesel pump. There is just one injection pump that has one fuel pressure mechanism. This has no relationship with the number of engine cylinders that the vehicle may have. There is a distributor in such diesel pumps that controls the injection order and distributes pressure fuel to each cylinder. There is a pump housing that has enough space to hold the internal components like the governor, the timer, and the feed pump. This has a compact design and thereby it is easier to control such pumps and maneuver them. Being lightweight also means that these pumps can operate at much higher speeds. This is why it is the best option for small engine sizes.

Conclusion

We hope with the help of this article, you can choose the type of diesel pump you need based on your requirements. You can always speak to a professional who is expert in the field of diesel pumps.

Comments